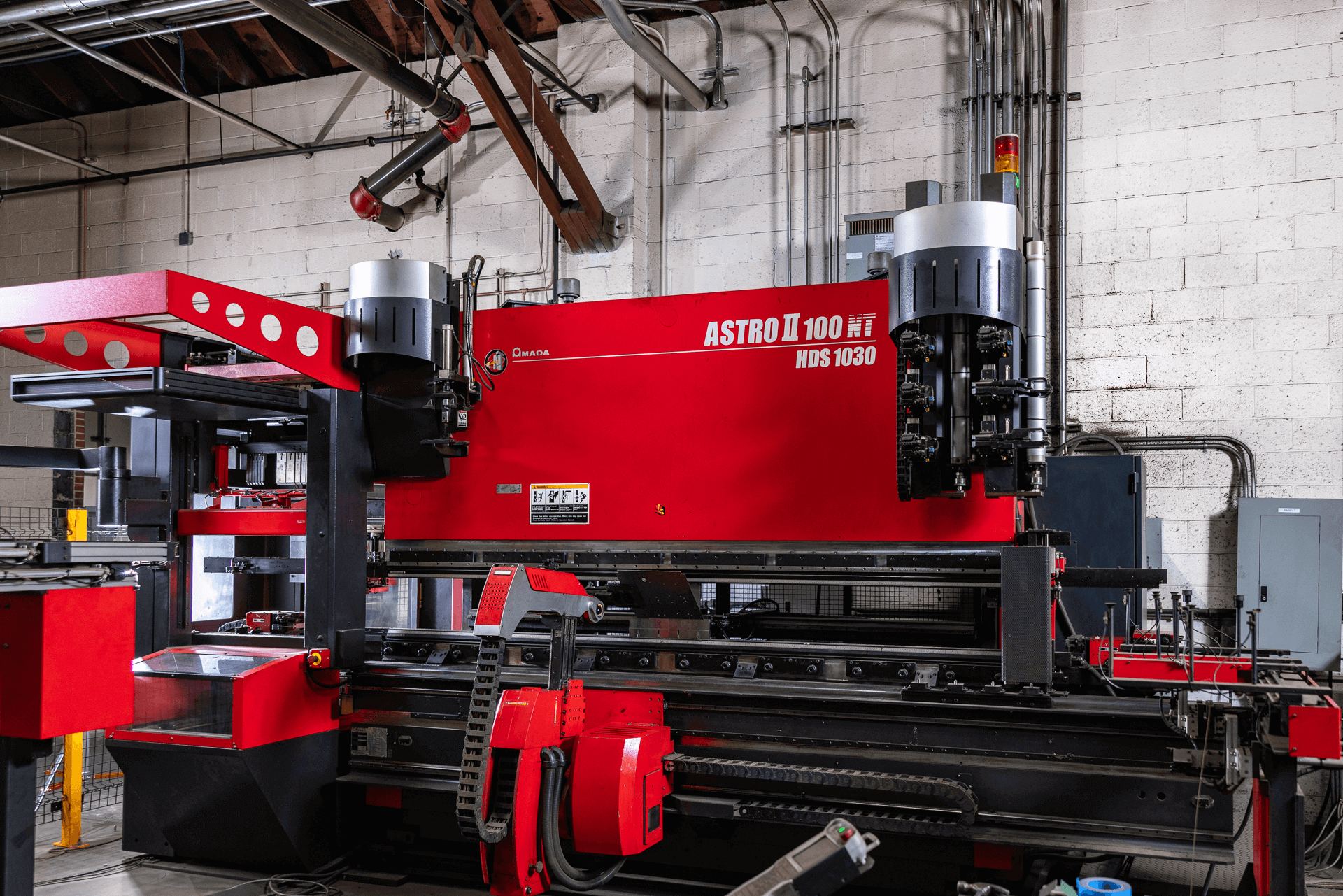

Achieve Precision with Seconn’s Bending Capabilities

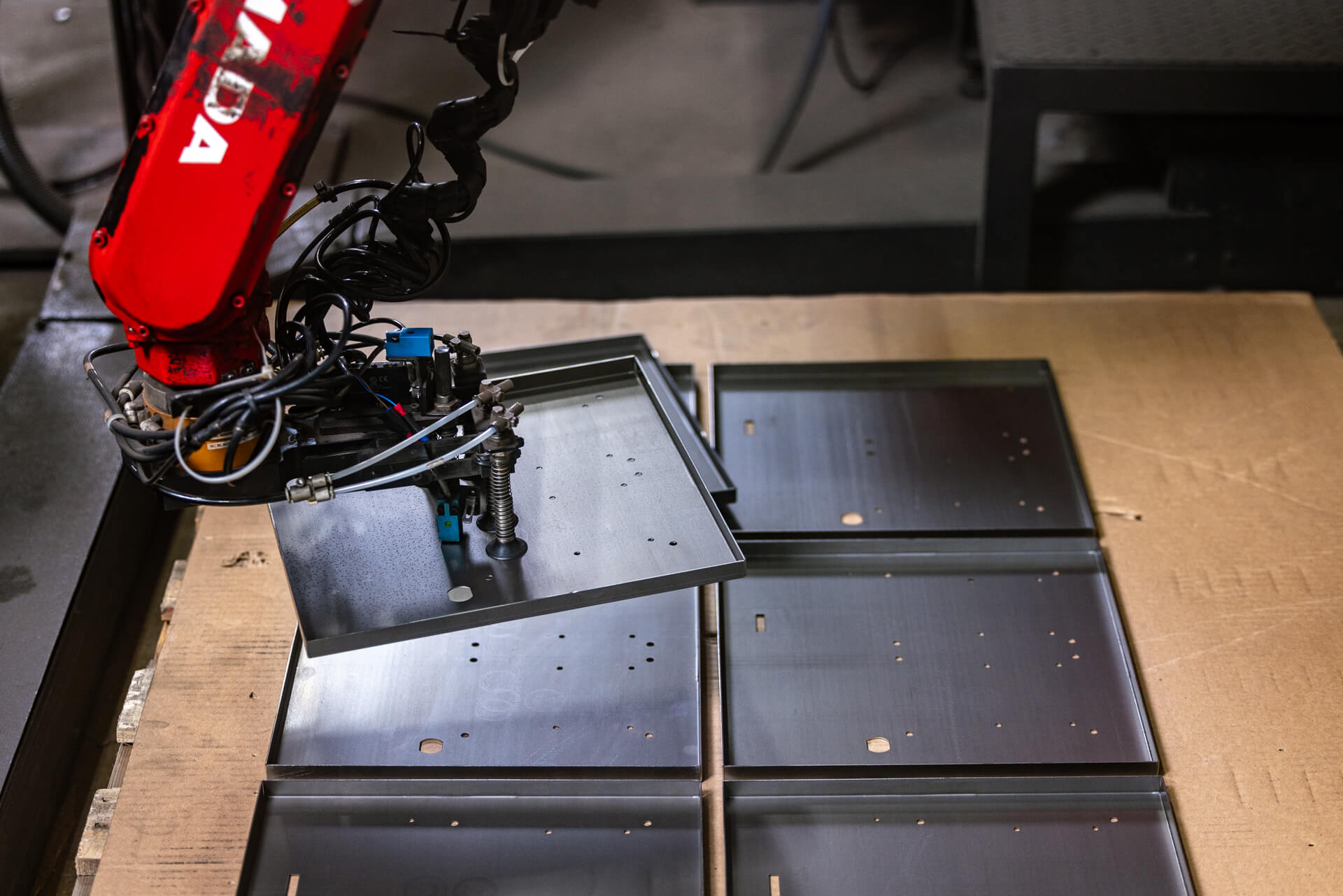

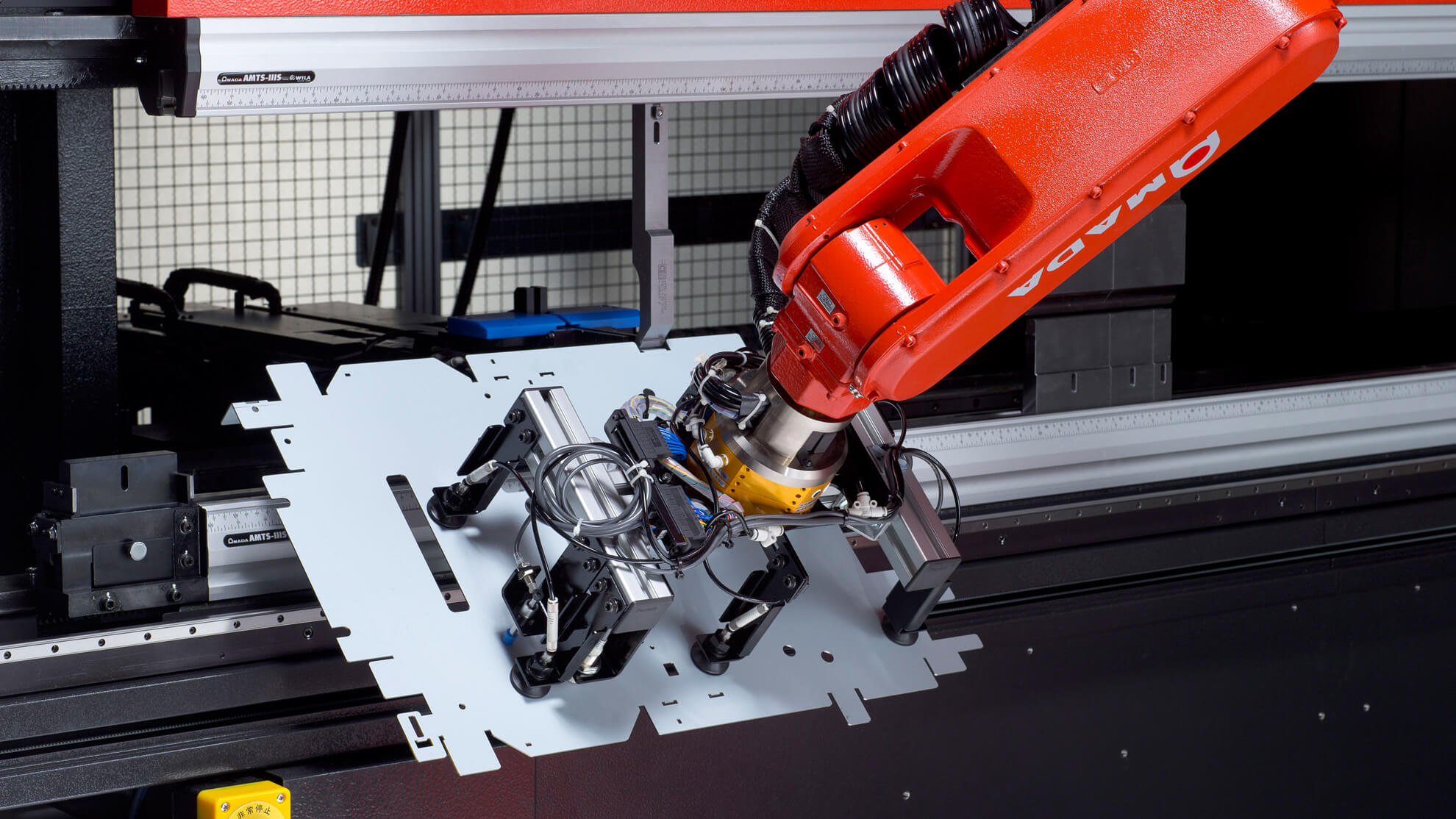

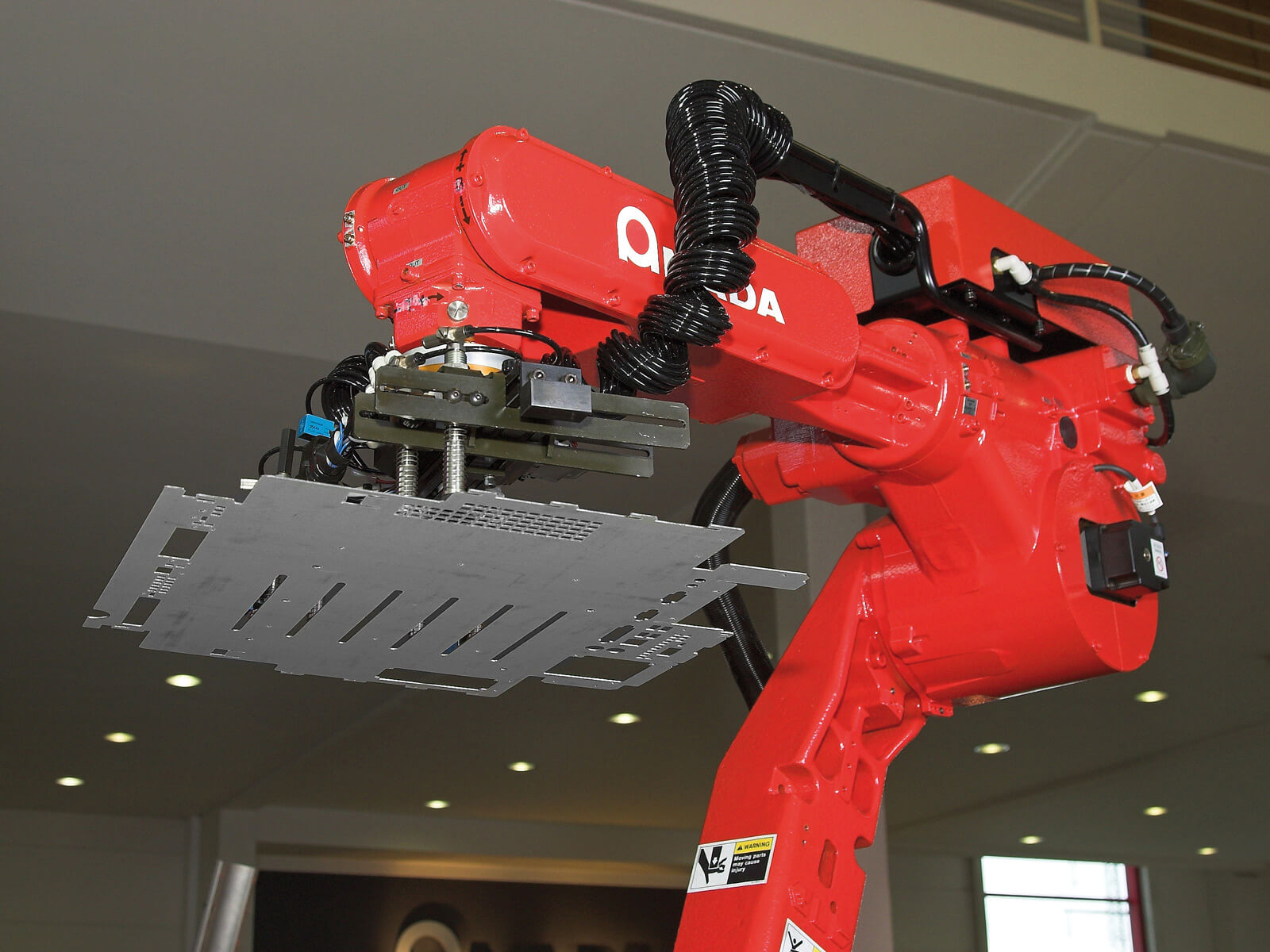

Seconn’s state-of-the-art sheet metal forming equipment can produce complex metal components that meet your business' needs. With an expert fabrication team and automated bending capabilities, we get the job done efficiently and accurately to ensure you get the parts you need on-time, every time.