One Facility,

Endless

Possibilities

Seconn’s facility is finely tuned to reduce waste,

increase flexibility, and improve production processes.

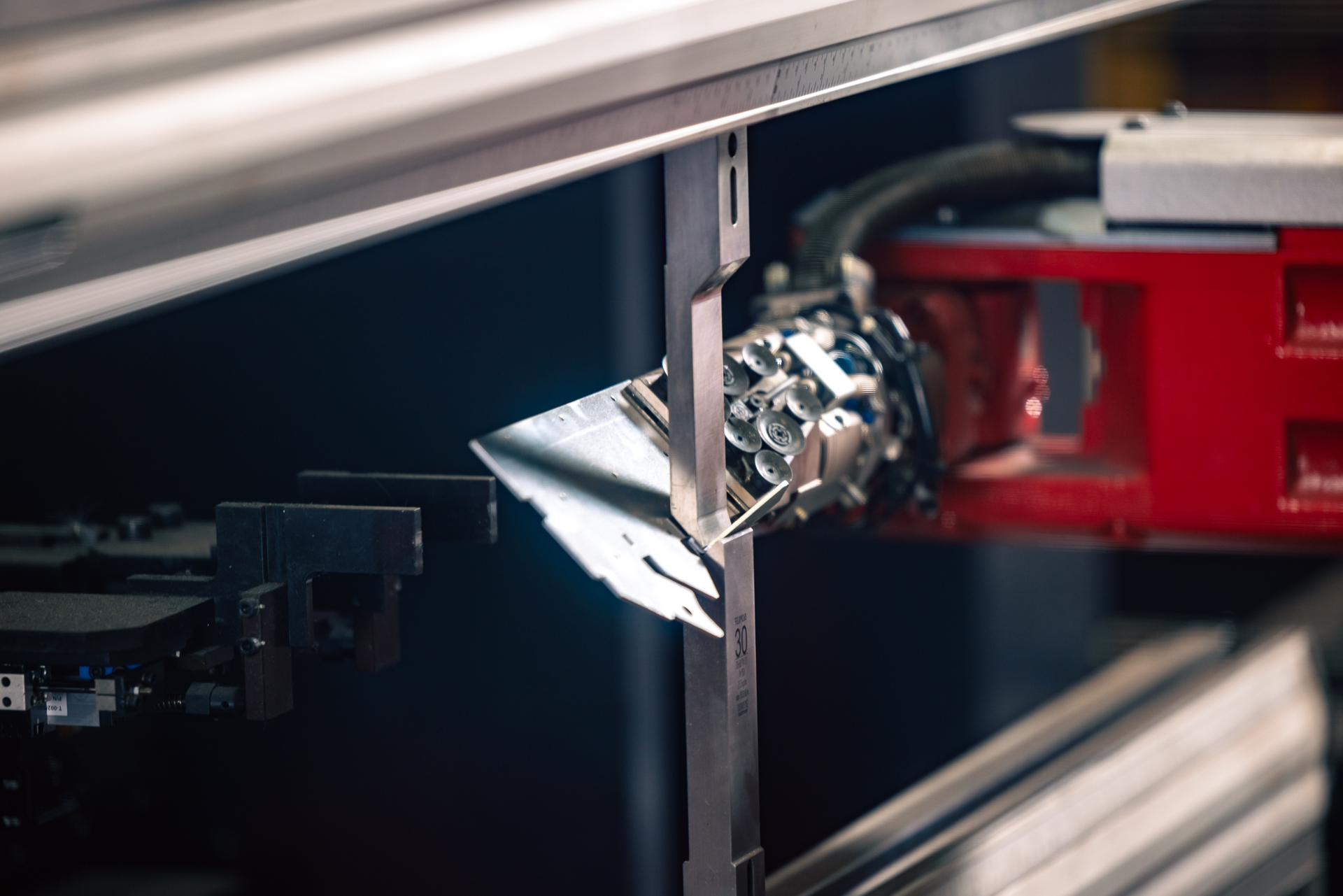

Optimized Processes for Streamlined Production

Seconn's main facility has undergone multiple renovations and expansions with a focus on lean initiatives to become an industry-leading manufacturing facility that houses state-of-the-art cutting, forming, welding, and powder coating machinery. Flexibility is ingrained in the structure of our production floor, with equipment redundancy, lean manufacturing, and adaptable production loops that enable our team to accommodate any customer requirement. Our facility is optimized for efficient and quality sheet metal fabrication, so you can get the products you need when you need them.

60,000 Square Feet

Our facility boasts 60,000 square feet of manufacturing space under one roof. Our abundant capacity allows us to offer comprehensive sheet metal fabrication services, including cutting/punching, forming, welding, and powder coating.

Adaptable Processes

Our production process is easily adjusted to accommodate the unique needs of each customer. We go the extra mile to understand product requirements and end uses to optimize production and increase product success.

Lean Manufacturing Practices

We utilize lean manufacturing practices to limit waste, increase production capacity, reduce errors, and shorten our lead times. Inventory is clean and organized, making it easy to identify when stock needs to be replenished.

Equipment Redundancy

Every process has a built-in redundancy of equipment and labor to reduce downtime due to equipment malfunction or staffing shortages. Our equipment is organized for maximum flexibility, so our customers are not impacted by delays.

Logical Loops

Our facility is structured in logical production loops, from raw material delivery to final product shipment. Work cells are adapted to each project, which creates easily identifiable stages to limit backtracking and confusion during production.

Innovative Technology

We are constantly evolving our production processes by investing in innovative equipment and technology that boosts efficiency and adds value for our customers. Key operations are highly automated to reduce labor, improve product consistency, and ensure on-time delivery.

Quality You Can See

ALL IMAGES

Your Metal Fabrication Partner

Since 2003, we’ve been committed to building lasting partnerships by providing high-quality fabrication solutions and unrivaled customer experiences. We’ve grown from a local job shop to an industry-leading metal fabrication manufacturer, delivering exceptional value and undivided attention to each customer.

“Our doors are always open. We're always excited to show off the investment in our team, technology, and facility. We encourage visitors to see what makes us unique and how we bring value to the table.”

- Rob