Balancing Cost and Quality in Custom Metal Fabrication Projects

Custom metal fabrication projects often involve a delicate and challenging balancing act. Experts must determine how to achieve the highest possible quality while keeping costs in check. This dilemma is common in industries where precision, durability, and aesthetics are essential.

The success of individual projects depends on cost-effective metal fabrication for optimizing designs and achieving the best price-to-precision ratio. Let’s explore the cost vs. quality battle and discuss the benefits of lean manufacturing in metal fabrication at Seconn.

Defining Cost and Quality: Custom Metal Fabrication 101

In most metal fabrication projects, “cost” refers to the financial outlay required to bring a project from concept to completion. It involves various factors and processes, including the cost of raw materials, technical labor, manufacturing, and additional custom metal fabrication services, like inspection, finishing and/or assembly.

Conversely, “quality” refers to the final product’s performance, precision, and durability. High-quality metal fabrication means parts meet exact specifications, function as intended, and withstand heavy or prolonged use.

A common challenge in custom metal fabrication is maintaining high quality standards while mitigating costs. Meanwhile, precision is non-negotiable, and safety is paramount in high-stakes industries such as medicine, aerospace, and automotive. Clients in these sectors demand top-notch outcomes but generally have budget constraints that cannot be overlooked.

Factors Influencing Metal Fabrication Costs

The need for cost-effective custom metal fabrication services means a constant push and pull between achieving the best quality and staying within budgetary limits. Therefore, understanding the key factors influencing price and product is crucial.

Material Selection

Today’s custom metal fabrication client must consider how materials impact the final price. For example, high-grade stainless steel might offer superior corrosion resistance and strength, but it’s more expensive than mild steel and other affordable alternatives. In many applications, the durability requirements can be achieved using less expensive materials with a secondary finish like powder coating or anodizing. The trade-off is worth contemplating, especially when evaluating non-financial needs like performance and safety.

Design Complexity

Complex designs can drive up costs because of the increased time and resources required for fabrication. However, intricate specifications can also lead to higher-quality renderings and achieve particular functionality or aesthetics. CAD and CAM optimize cost and quality, allowing for precise modeling and simulation. Seconn experts can also help identify issues before fabrication to reduce the likelihood of costly rework.

Manufacturing Processes

When designing the part, it is essential to consider the required design features, and the manufacturing processes needed to achieve them. Often, there is more than one process that can create a feature. Things to consider when designing the features are the precision required, the strength and/or durability of the feature, the aesthetics, and the number of parts required. Many procedures, like progressive stamping, produce parts with excellent precision but are cost-prohibitive unless sufficient volumes justify the tooling cost.

Labor and Expertise

Proficiency is critical for lean manufacturing in metal fabrication. However, this expertise comes at a cost. Experienced metal fabricators delivering precision work and innovative problem-solving are invaluable, but their services will naturally command a higher price. Therefore, investing in skilled labor means preventing expensive mistakes and ensuring projects are always completed to the highest standards.

Inspection and Testing

When looking to ensure the quality of parts, many designers fall back on Inspection and Testing to deliver the desired results. Quality assurance in manufacturing is an essential component of any top-level operation but it comes at a cost. In addition, when sampling large quantities, it doesn’t always catch minor, critical defects. Rather than inspecting in quality, designers can save costs by limiting inspection requirements to essential items and designing features and processes that reduce the chances of errors in those critical areas.

Strategies for Cost-Effective Metal Fabrication of Custom Designs

Lean manufacturing processes reduce waste and improve efficiency, so streamlining processes and eliminating unnecessary steps can optimize resource use and allow fabricators to achieve higher-quality results at lower costs.

Seconn has successfully reduced lead times by over 33% through standardizing processes, allowing our teams to provide top-notch end products more quickly and cost-effectively. Our lean, collaborative design and engineering approach minimizes rework, pinpoints problems, and allows for rapid adjustments that save time and money.

Leveraging Technology and Innovation

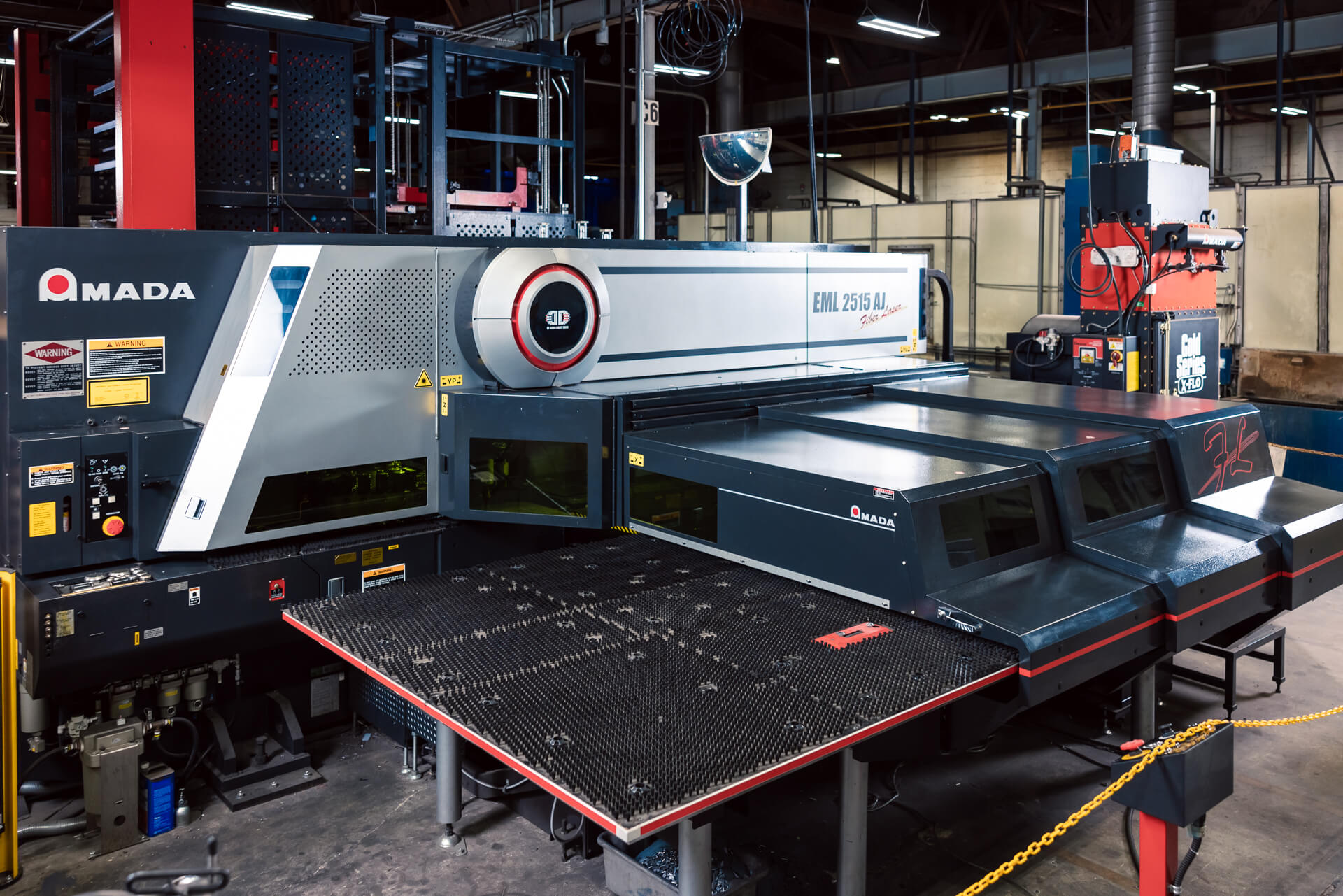

Advanced manufacturing and fabrication technologies help experts maintain high standards while controlling costs and supporting client goals. At Seconn, for example, our robotic bending and automated laser cutting offer greater precision and consistency, reducing the likelihood of errors that can slow project completion and increase expenditures.

Our continuous investment in cutting-edge metal fabrication technology demonstrates our commitment to superior results and competitive pricing. We believe the key to unlocking mastery is balancing cost and quality through tech, innovation, collaboration, and resourcefulness.

Seconn Fabrication experts are highly trained, and dedicated to integrity, proficiency, and affordability. Our mission is to forge strong customer relationships as a trusted partner in custom metal fabrication, lean manufacturing, and navigating the complexities of cost vs. quality.

Tips for Evaluating Cost vs. Quality

Customers who focus primarily on fabrication price inadvertently put themselves in a matrix to sell products for pennies. However, those who can appreciate quality materials, innovative techniques, sophisticated methodologies, and procedural transparency will benefit from custom metal fabrication services at Seconn.

Consider the true cost of a project beyond the initial price tag. Quality, experience, and reliability are all crucial factors contributing to the final outcome. What’s worth investing in to ensure the immediate and future success of your project? Our team can help you decide.

Maximize Quality and Budget with Seconn's Expert Metal Fabrication

At Seconn Fabrication, we don’t see the battle between cost and quality as a compromise but as an opportunity to innovate and excel. Our custom metal fabrication experts provide top-tier results that meet precise specifications and respect varying budgets. Don’t settle for less when you can have the best of both worlds.

Contact Seconn today to discover how we can turn your next project into a masterpiece of precision and affordability. Trust us to fabricate your vision with nothing less than cost-effective perfection.

Related Resources

Get the solutions you need when you need them.

Reach out to request a quote for your sheet metal fabrication project and see what Seconn can do for you.