Case Studies

Learn more about how we collaborate with clients to build effective sheet metal fabrication solutions.

Bauer, Inc.

Bauer, Inc.

"Seconn has been a valuable supplier to Bauer for our fabrication needs. From the start of our relationship, they took the time to understand our business, technical requirements and overall expectations. Their team has decades of experience, from engineering to manufacturing, and it is evident in the high quality of the finished product. As a customer, we can always rely on Seconn to deliver on-time and they stand behind their work. Our relationship has evolved into a true partnership that makes us both successful!"

-Mark Auletta

Vice President of Operations – Bauer, Inc.

Challenge

Our client needed to find a fabrication shop to help them with overflow. On-time delivery and critical design changes were pain points. They were looking for a strategic partner with the technical expertise to smoothly transition through minor changes while meeting manufacturing standards and on-time-delivery.

Solution

Seconn’s team took on the project collaborating with manufacturing, engineering, and sales to truly understand Bauer’s business and their needs to move projects forward and meet critical deadlines. In order to truly partner with Bauer, the team engaged in open two-way communications implementing design changes, blueprint improvements, standardization of common parts, two-way site visits, standard information/file transfer and on-going feedback to ensure their expectations were met including on-time delivery and high quality.

Results

Almost immediately, the changes resulted in shortened schedules. Standardizing the flow of information and common parts, as well as improvements to the prints reduced time in estimating and pre-production/engineering allowing projects to get into production faster. Once to production, the improvements reduced non-value added time and costly rework which moved the products through faster. Overall lead times were reduced by more than 33%.

Excel Tire Gauge, LLC

Excel Tire Gauge, LLC

Excel Tire Gauge has partnered with Seconn Fabrication for over almost 2 decades. And it is a partnership in the truest sense of the word. Our companies work seamlessly together with vision, direction and the goal of satisfying our customers – our shared customers.

Seconn has worked closely with Excel on our SC05 model. Together, we have streamlined costs, efficiencies, production and delivery, to supply the US market with one of our premier air machines, seen and used at many of America’s top gas stations and tire shops.

-Jay Nelson

Owner–Excel Tire Gauge, LLC

Challenge

Our customer needed to reduce the overall costs on their product in order to be competitive and increase sales on the national level.

Solution

Seconn’s engineering and manufacturing teams met with Excel to lean out their SC05 model. Together, we implemented design changes to improve manufacturability, changed materials, and made process improvements to reduce material cost and manufacturing labor.

Results

Through collaboration with both teams, Seconn and Excel were able to reduce the overall manufacturing cost of the SC05’s by 15%, making them competitive on the national level and increasing revenue by over 20%.

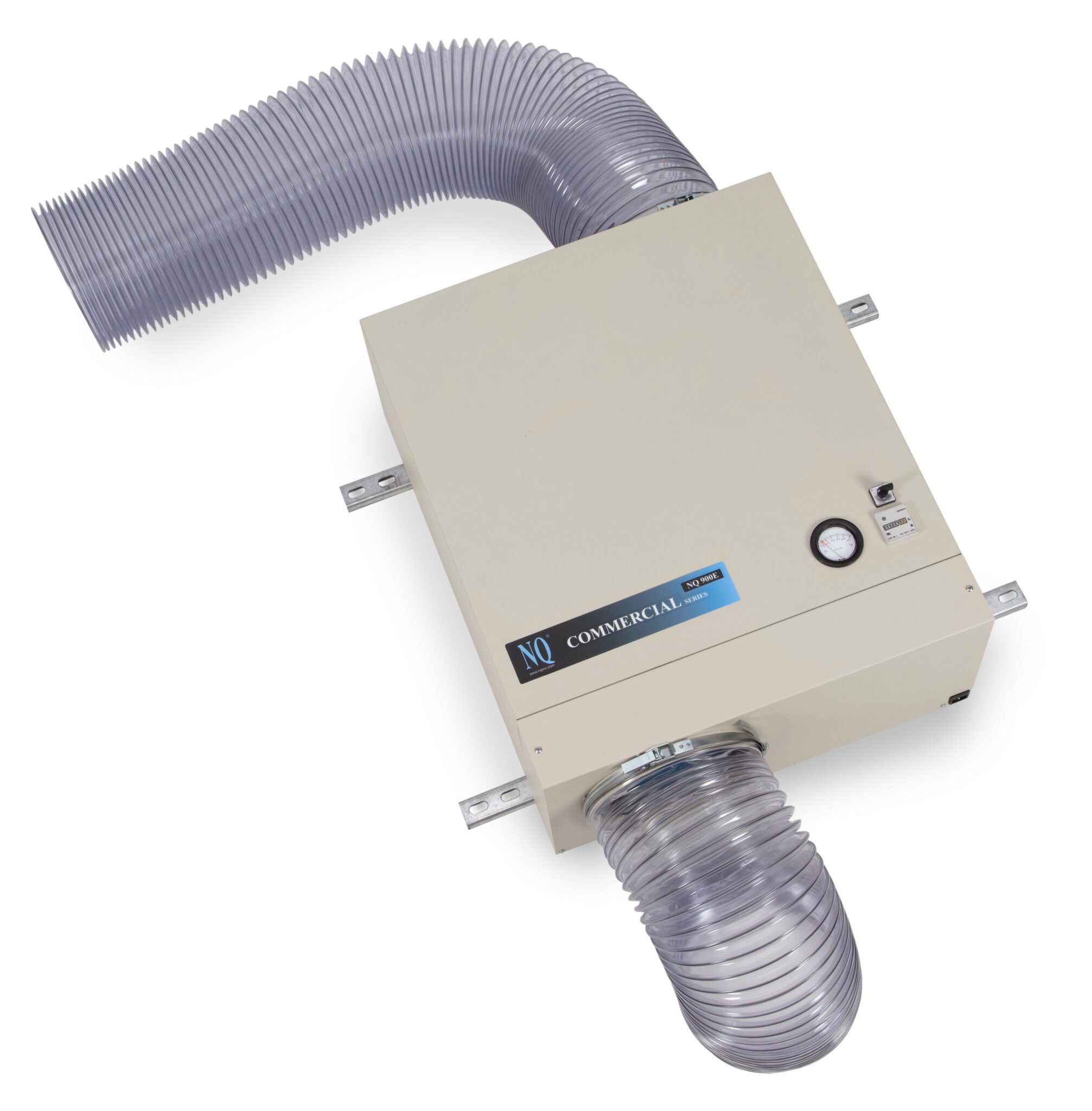

NQ Industries, Inc.

NQ Industries, Inc.

I’ve worked with Rob (Marelli) since 1997, both when he managed another company and since he started Seconn. Since its founding (in 2003) Seconn has been an integral partner in NQ Industries, Inc.’s manufacturing operations. The physical proximity to our Connecticut based operation is critical in our capabilities to produce and ship products on time and with projected expansion along with us as we grow as a company. I would recommend Seconn to anyone within the New England area who is in need of fast, personable, and reliable steel supply.

-Bill

CEO and Founder –NQ Industries, Inc

Challenge

Our client needed a fabrication supplier that could provide all services, one-stop shopping, and the expertise to optimize product design. Time to market was absolutely critical to take advantage of this customer’s dynamic marketplace, as was ability to ramp up dramatically and quickly.

Solution

Seconn’s technical team jumped right in by evaluating current customer designs and worked together via file transfers, conference calls, emails, and in-person meetings to improve designs by reducing costs and optimizing manufacturability. Over time Seconn helped in the design of many products and supported NQ’s rapid launch initiatives by delivering on time and implementing manufacturing scale up initiatives.

Results

The relationship continues to be personally rewarding for both companies. Work doesn’t always have to feel like work and the mutual respect and friendship makes our business with NQ a true joy. Over the years, with multiple product launches, both companies have prospered nicely. One example covers the period from 2020 through 2021, where Seconn produced well over 300 separate jobs for NQ, bringing all resources to bear to meet excessive end-use customer demand.

Accu1

Accu1

“Working with Seconn is proving to be vital for my business. I spend a lot of time in the field with my customers, listening to their needs to refine our product. When I take these ideas to Seconn, they are very receptive and offer improvements that stem from their expertise in manufacturing. As a small business owner, I value the relationships I have with my key vendors. Seconn has a personable quality that isn't always easy to find.”

-Richard Lodigiani Jr.

Vice President of Operations, Accu1 Direct

Challenge

Accu1 Direct, a leading manufacturer of insulation blowing equipment, was getting feedback from their customers regarding improvements to their products that would improve their performance in the field. They had a great team in house to prototype their improvement ideas but didn’t have the engineering team to work through the details and create drawings for fabrication. Their other vendors were reluctant to dedicate resources to improving the products or provide files for fear Accu1 would go elsewhere. They had all these great ideas to improve the product and grow sales but couldn’t bring them to the market in their product lines.

Solution

Seconn met with the key members of their team to understand their ongoing needs. Not only did they need to incorporate their current ideas into their products, but they also needed a partner who would help them incorporate improvement ideas in the future and provide open feedback about the changes.

We had done some business over the years but had only produced a few of their products. Before their next order we took our existing knowledge of their products, their sketches and samples of prototype ideas and got to work incorporating the changes they needed into the designs. Our engineering and production teams met multiple times with Accu1, not only incorporating their changes but understanding the struggles they were having with the machines and truly getting to know their markets and strategy.

Soon after we had redrawn most of their products and incorporated all the changes into the multiple machines. While this was happening, they continued to meet their customers and get feedback on more improvements. We mapped out a window when new changes could be incorporated without interrupting the flow of products. As soon as the first batch of machines was hitting production, we were already busy incorporating the new improvements into the drawings for the next runs.

Results

With a solid engineering package and a vendor who not only knows their products and business but is actively committed to helping them improve, Accu1 is now able to continuously solicit feedback from their customers. They are confident that they can evaluate the feedback, request changes to their product line on a regular basis and get improvements incorporated in a timely and economic manner. This key differentiator has helped them not only improve the performance of their products for their customers, but also expand their business and add new customers.

Encon Evaporators

Encon Evaporators

Challenge

Seconn has been manufacturing Thermal Evaporators for Encon Evaporators, an industry leader in the design and manufacturing of Industrial Wastewater Evaporation Systems, for nearly 10 years. After so many years as successful partners, both teams were looking at ways to grow the relationship.

Encon recognized a significant growth opportunity in their business relating to wastewater evaporators for highly corrosive materials. These units require a combination of 6-Moly (254SMO and/or AL6XN) and 316L Stainless steel and they had only one fabricator who was willing to build these units with this unique combination of materials.

Encon’s evaporators are complex, with specific quality requirements. They had experienced growing pains when onboarding new suppliers and as such wanted to utilize an existing supplier who already understood their products and business.

Solution

Seconn and Encon were actively working to expand our partnership, with regular meetings between our management teams. Seconn had previously only done 316L Stainless Steel units for Encon and have never worked with 6-Moly, but when the opportunity to grow the partnership in this area was brought up, we were up to the challenge.

Immediately Seconn got to work researching the material; determining the best way to cut, form and weld it. Every other week Seconn and Encon met virtually to discuss the material and develop a plan of attack.

After the initial testing success, it was time to try it out on full units. Encon contracted with Seconn to fabricate three 260 gallon per minute thermal evaporators for a project they needed. The units were like units Seconn had done previously, but with 6-Moly replacing 316L Stainless Steel for the portions in contact with the corrosive material.

Results

Seconn fabricated the units, assuring that all specifications were met, including leak testing and delivered them ahead of schedule to Encon. With the completion of this project Encon was able to expand its supply chain for this material while still using a fabricator who already knew and understood their business. This allowed Encon to expand their revenue stream and capture additional market share.

Partner with Seconn

Get in touch with a team member to get started on your sheet metal fabrication project.